Quality inspection with Kuka Robot and 3D scanner

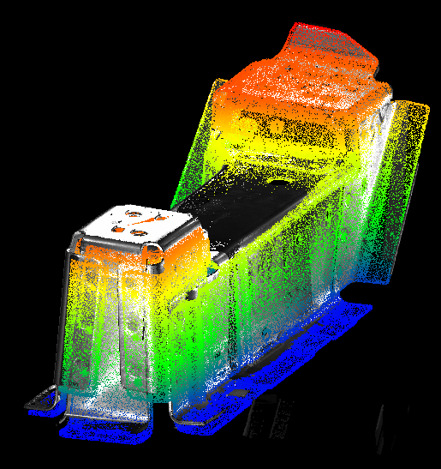

In this project, we implemented quality control using a 3D scanner from Photoneo in conjunction with a Kuka robot. The project’s primary objective was to extract key features from the car part workpieces and meticulously inspect them for accuracy. To achieve this, we devised a process involving assembling the entire part from multiple-point cloud captures. This innovative integration has enabled the car manufacturer to conduct comprehensive inspections on all products emerging from the production line, eliminating the need for ad-hoc human inspections and ensuring consistent quality throughout the manufacturing process. This work is part of my students’ thesis, authored by Andrej Chmurciak and Samuel Kostur.

The work was done as part of cooperation between academia and the private sector